Robot machines technician for Industry 4.0

The Robot Machines Technician for Industry 4.0 is responsible for setting up, operating, and maintaining robotic machines in industrial settings. They have knowledge of robot components, characteristics, and applications, and can distinguish between advanced and collaborative robots, including their types and the differences from traditional industrial robots. They can program, set up, and monitor industrial robotic arms, perform basic maintenance, and identify risks and safety issues during robot operation. They also understand maintenance indicators and diagnostic techniques to ensure optimal robot performance.

Lesson 1 - Simulation environment

Students will learn how to use the simulation tool. Free movements of the manipulator will be carried out in order to know the different panels and options provided by the simulator.

Lesson 2 - Basic programming

Using digital twins, the movement commands of the manipulator will be illustrated, as well as the handling of the gripper.

The setup for this lesson consists in a robotic arm that have to move objects in specific positions. Students will be asked to do a basic pick and place task and to build a tower.

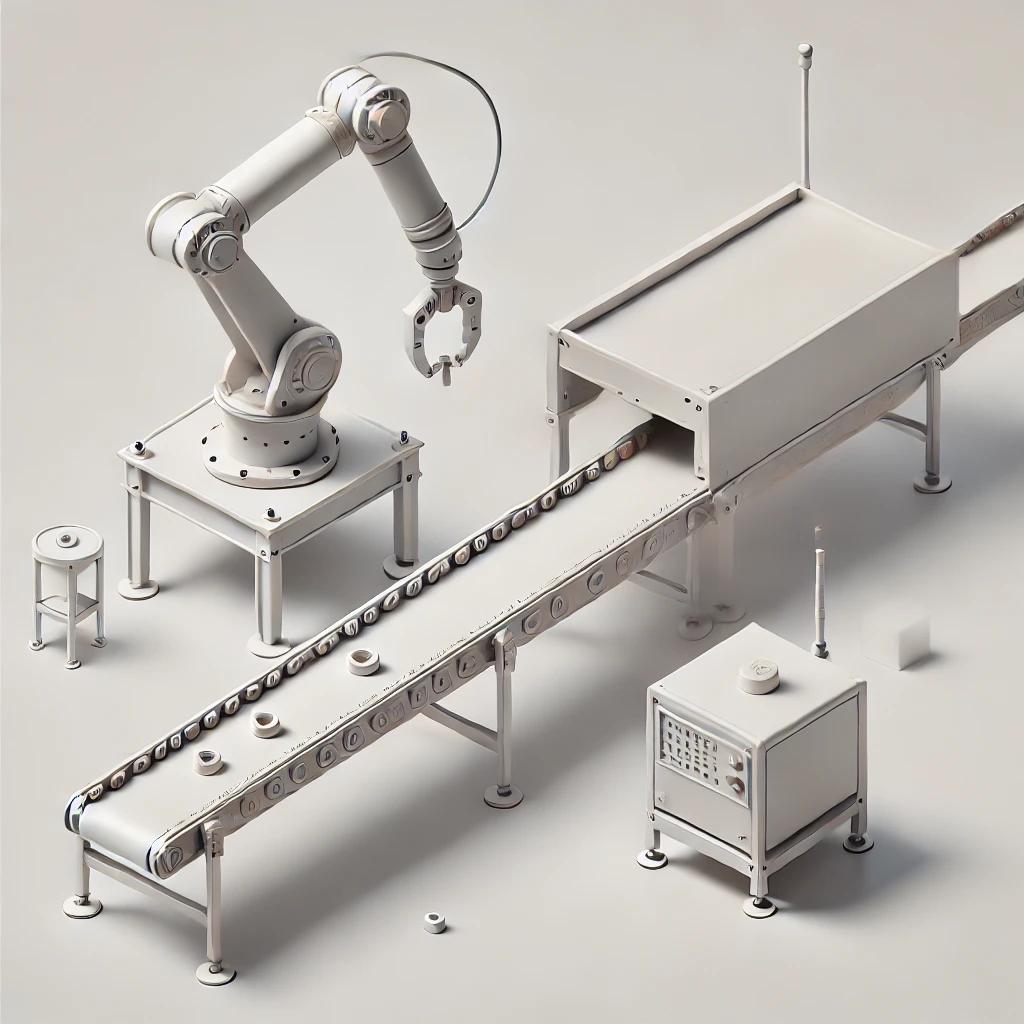

Lesson 3 - Sensors and Actuators

Students will learn how to utilize digital twins, with an emphasis on demonstrating the use of digital input and output signals connected to the manipulator. These signals will enable the activation of actuators and the reading of information from sensors.

The setup will include a parts feeder and a conveyor belt. The feeder will be actuated via an output signal, causing it to tip a part onto the conveyor belt. The conveyor belt will then be activated to move the part until it reaches a barrier sensor positioned at the end of the belt. Once the sensor is triggered, the conveyor belt will stop, and the manipulator will pick up the part and transport it to its designated position.

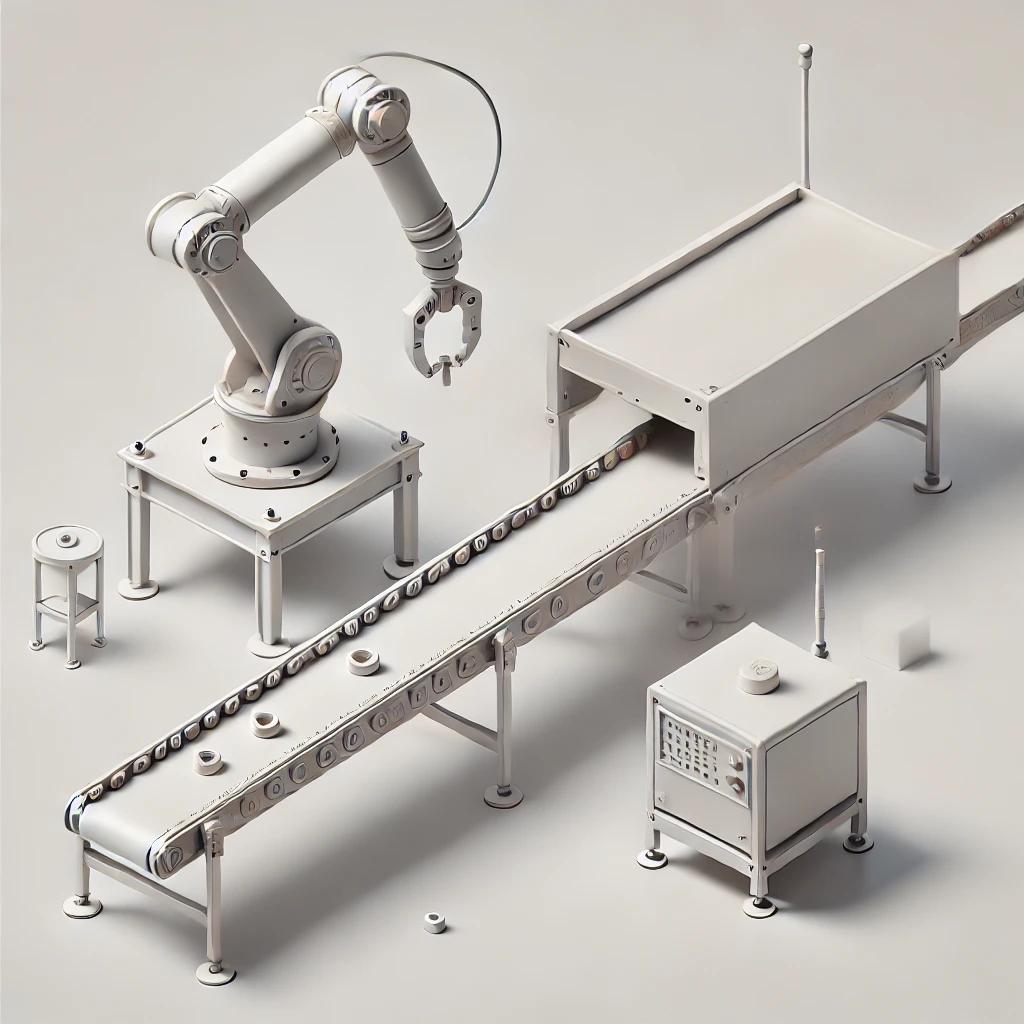

Lesson 4 - Obstacle avoidance and sensors and actuators programming

The setup will include a parts feeder and a conveyor belt with some obstacles in the path of the manipulator. The trajectory of the manipulator will have to be modified, by means of the different configurations of its kinematic model, or through via points in order to avoid collisions.

Fill-in and send the reservation form to start the process that will take you through the Robot machines technician for Industry 4.0 module